CAD for microfluidics

By Joshua Gomes

Choosing the right CAD strategy can make or break your microfluidic project.

2D CAD - Easy to learn, but imprecise link to 2D CAD - Easy to learn, but imprecise section

Illustration software

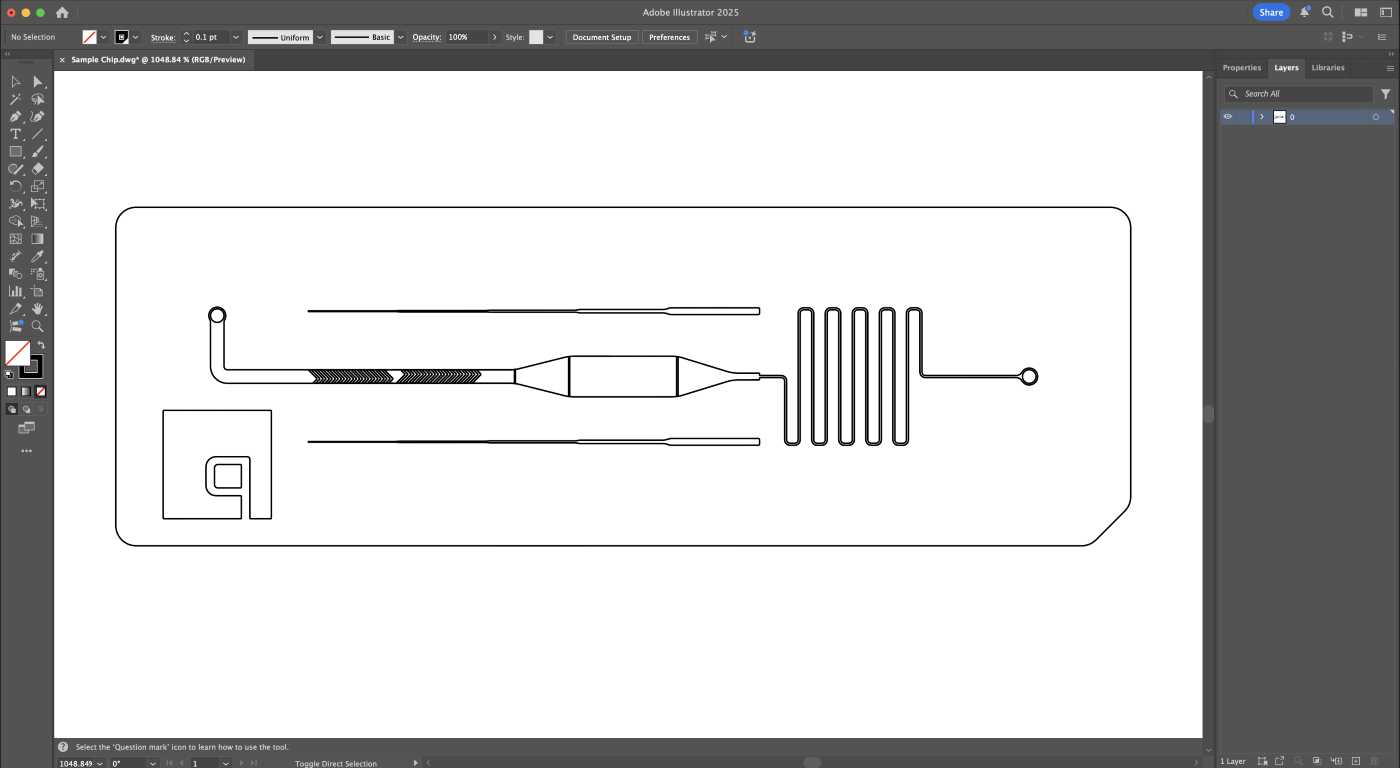

Vector programs like Adobe Illustrator, Affinity Designer, or Inkscape are inexpensive ways to sketch up a concept for a microfluidic chip, but they lack the parametric design features needed to control the exact dimensions of your geometry.

2D microfluidic device in Adobe Illustrator.

2D CAD

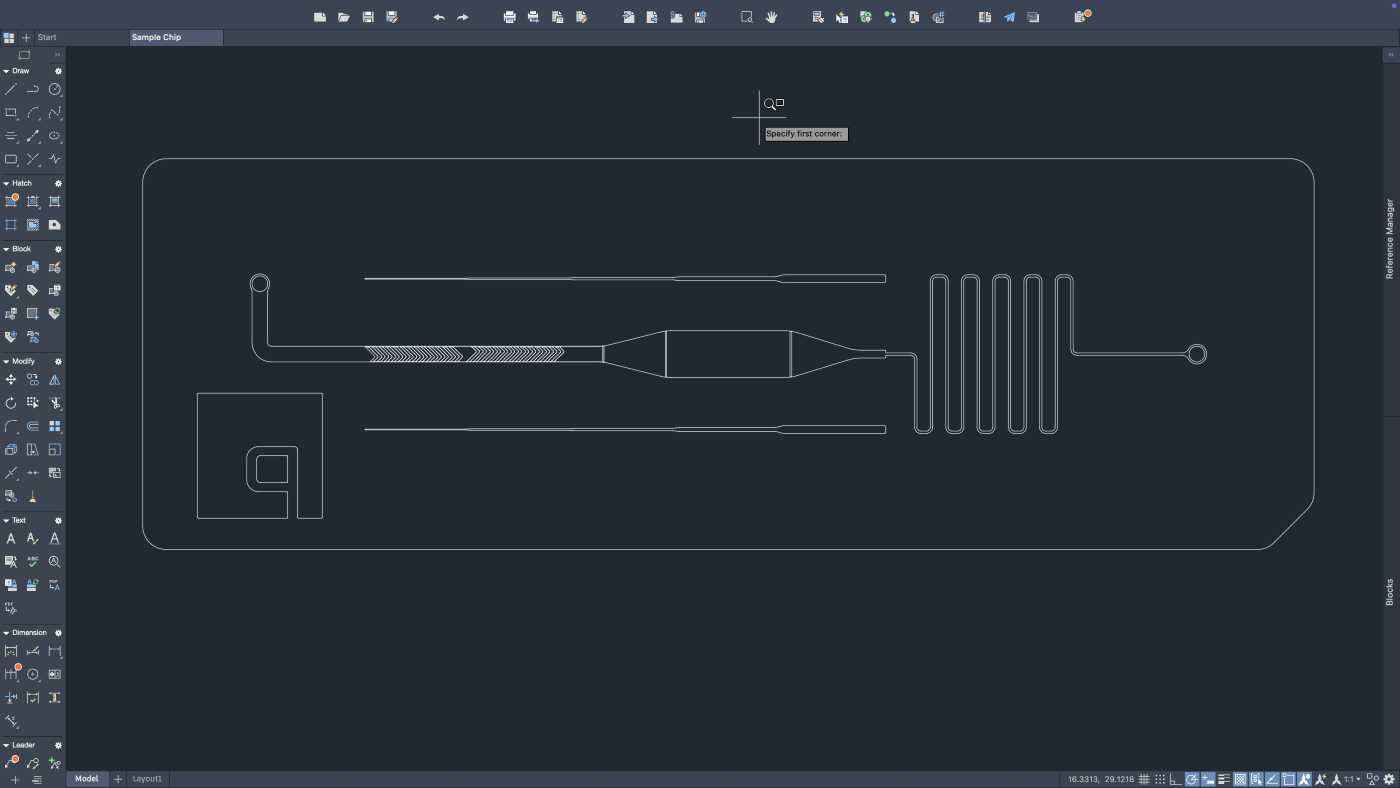

Parametric 2D CAD tools like AutoCAD and DraftSight give you precise control of your microfeature dimensions. They are the go-to programs for designing photomasks used to produce PDMS devices by soft lithography.

2D microfluidic device in AutoCAD.

While both strategies are inexpensive and easy to learn, they don’t capture the full picture of your device in three dimensions and are incompatible with most fabrication techniques like 3D printing, micromilling, and injection molding.

Our CAD experts at Parallel Fluidics can help convert your 2D CAD drawing into a full 3D model at no charge to help you get ready for manufacturing.

3D CAD - Powerful, but complicated link to 3D CAD - Powerful, but complicated section

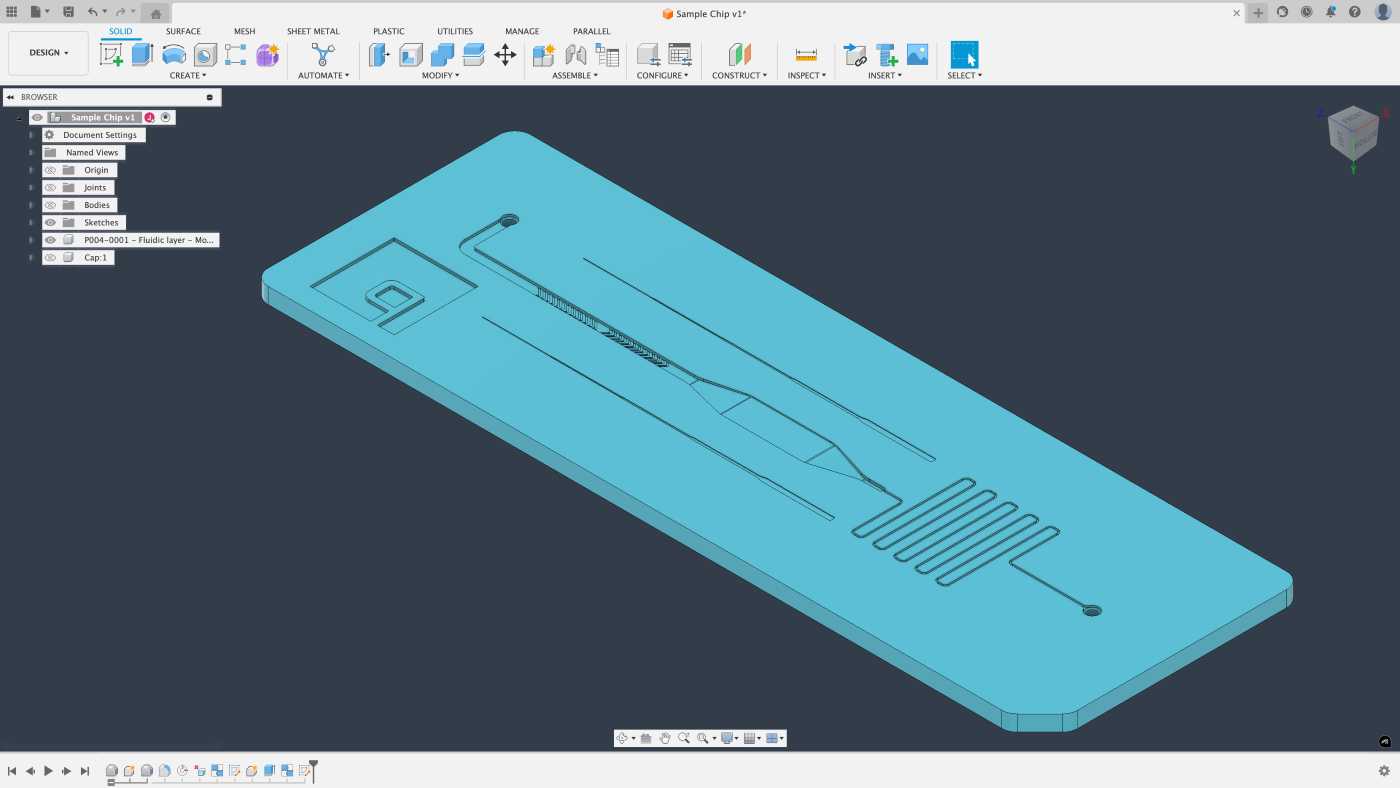

3D CAD programs are the industry standard for defining the exact details of your microfluidic device. The most common packages used by our customers are SolidWorks from Dassault Systèmes and Autodesk Fusion. While extremely powerful, the steep learning curve can frustrate new users.

3D microfluidic device in Fusion 360.

Schedule a workshop with our engineering team to work through the challenges of 3D modeling for microfluidics.

No CAD - Let us help link to No CAD - Let us help section

If you have a concept for a microfluidic device, but aren’t interested in investing the time and effort to learn complicated CAD software, we can help! Our engineers will work with you to understand your requirements and build the 3D model for you.